Oil & Gas Pipeline Inspection Software for NDT

Creaform’s pipeline inspection software delivers complete 3D visualization and automatic defect detection for corrosion, denting, and wrinkle analysis in pipeline integrity assessments.

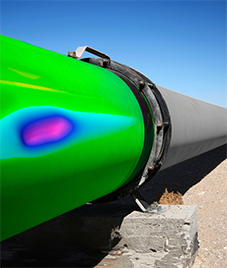

3D Corrosion Analysis with Full Surface Coverage and Virtual Pit Gauge

Unlike the pit gauge, pipeline measures both internal and external corrosion and provides complete 3D visualization for in-depth analyses. Once corroded surfaces are digitalized, the algorithm simulates a virtual pit gauge that covers the whole surface.

Extraction is measured as with the manual tool but with higher accuracy. The technique ensures 100% surface inspection coverage, better repeatability, and traceability over time.

Damage detection and reporting On-site, instant, and automatic |  |

Calculations Estimated burst pressure (ASME B31G compliant) | |

Virtual pit gauge capability Near welds and obstacles |

Denting and Mechanical Damage Detection with Automatic 3D Depth Analysis

Pipeline provides key NDT pipeline inspection functionalities, including the automatic detection of maximum depth and size—difficult to find with traditional measuring methods. Once the surface is digitalized, pipeline computes the pipeline's diameter, curvature, and circumference for automatic defect detection and measurement.

Automatic detection Automatic maximum depth detection |  |

Measurement Depth measurement using straight edge | |

Regulations B31.8R-2018 Strain-based analysis |

Wrinkle Analysis with 3D Crest-to-Trough and Diameter Calculations

Pipeline’s wrinkle analysis module is programmed to calculate the crest-to-trough depth of the ripple in addition to the wavelength, circumferential extent, and diameter restriction—enhancing the quality of pipeline inspection analyses and reporting. By fitting a perfect cylinder on the damaged pipe, pipeline finds the highest and lowest points of the wrinkle and extracts the depth wavelength of the damaged area.

Crest to trough Crest-to-trough depth of the ripple |  |

Diameter Diameter restriction | |

More calculations Wavelength |

Advanced pipeline inspection functionalities

| Corrosion in mechanical damage | In-line inspection (ILI) correlation tool | Pressure vessels - Large diameters |

| Assessing material loss from deformation is now easy with pipeline software. The NDT solution offers sophisticated tools and functions to extract corrosion depth inside a pipe’s mechanical damage. | Pipeline monitors ILI performance levels by correlating smart-pig data against pipeline 3D scanning or imported UT data. The interface has been optimized to compare features' depth, length, and width in just one click. | Pipeline supports the inspection of cylinders with diameters of up to 152m to enable inspection teams to assess large cylindrical components, such as pressure vessels and distillation columns. |

Chose the right scanner for you

| HandySCAN 3D|BLACK series | HandySCAN 3D|SILVER series | HandySCAN 3D|MAX series |

| Accuracy: 0.025 mm (0.0009 in) Light Source: 30 blue laser lines (+1 extra line) Accreditation: ISO 17025 | Accuracy: Up to 0.030mm (0.0012 in) Light Source: 14 blue laser lines (+1 extra line) | Accuracy: 0.075mm (0.0030 in) Light Source: 38 blue laser lines Accreditation: ISO 17025 |